Top Tools for Concrete Adhesion Success

Share

When it comes to concrete adhesion success, you'll need to wield the right tools and techniques to guarantee a strong, lasting bond. For bonding, reach for epoxy-based adhesives, and don't forget to prep the surface with grinders, scarifiers, and shot blasters to increase contact area. Precise mixing and application tools, like high-quality mixing paddles and notched trowels, are also essential. To verify bond quality, turn to pull-off testers, tensile testers, and shear testers. With these tools in your arsenal, you'll be well on your way to achieving the best adhesion - but there's still more to explore to guarantee your concrete project stands the test of time.

Key Takeaways

- Effective surface preparation tools, including grinders and scarifiers, ensure a clean and roughened surface for optimal adhesion.

- Precise mixing and application tools, like high-quality mixing paddles and notched trowels, guarantee consistent bond strength.

- Curing and protection options, such as moist curing and protective coatings, enhance durability and reduce shrinkage.

- Testing and inspection tools, including pull-off testers and tensile testers, verify bond quality and identify defects.

- Following manufacturer's instructions and safety precautions is crucial for successful concrete adhesion.

Essential Adhesives for Bonding

Achieving a strong bond between concrete and various substrates or materials relies heavily on selecting the right adhesives. You'll find that epoxy-based adhesives are commonly used for bonding concrete due to their exceptional strength and durability.

There are several epoxy types to choose from, each with its unique characteristics and applications. For instance, 100% solids epoxies are ideal for high-traffic areas, while epoxy-acrylates are better suited for bonding concrete to metal or glass surfaces.

When it comes to bonding techniques, you'll need to take into account factors such as surface preparation, mixing ratios, and application methods. You may opt for a mechanical bonding technique, which involves creating a rough surface for the adhesive to bond to, or a chemical bonding technique, which relies on the adhesive's chemical properties to form a strong bond.

Regardless of the technique you choose, it's crucial to follow the manufacturer's instructions and take necessary safety precautions to guarantee a successful bond.

Surface Preparation Tool Essentials

You've selected the right adhesive and bonding technique, but now it's time to focus on the often-overlooked yet essential step of surface preparation. This critical phase lays the foundation for a strong bond between the concrete substrate and the adhesive. To achieve maximum adhesion, you must guarantee the surface is clean, dry, and free of contaminants.

Invest in surface cleaning techniques that effectively remove dirt, oil, and other substances that can compromise the bond. This may involve using wire brushes, scrubbers, or solvents to remove surface impurities.

Additionally, employ substrate assessment methods to evaluate the surface's porosity, texture, and moisture levels. This information helps you choose the most suitable surface preparation tools and techniques for your specific project.

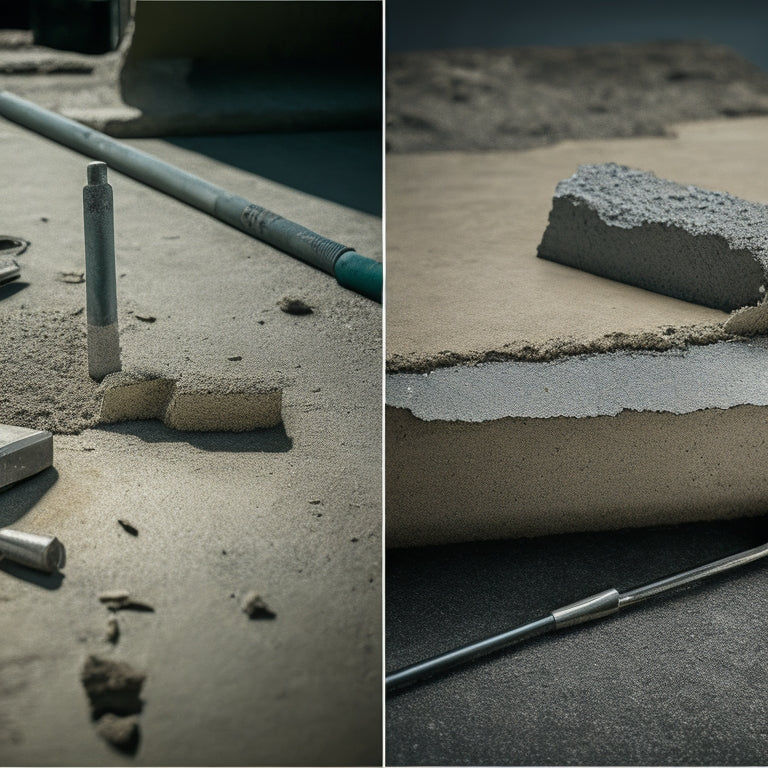

Some essential surface preparation tools include grinders, scarifiers, and shot blasters. These tools help to roughen the surface, increasing the contact area between the substrate and adhesive, and promoting a stronger bond.

Mixing and Application Tools

Mixing and applying adhesives demands precision and control to secure a strong, consistent bond. You'll need the right tools to guarantee accurate mixing ratios, thorough blending, and efficient application.

Invest in a high-quality mixing paddle or drill attachment, designed specifically for adhesive mixing. These tools enable you to achieve uniform consistency and prevent air pockets, which can compromise bond strength.

When it comes to application methods, you have options. For smaller areas, manual application tools like notched trowels or squeegees are effective. For larger projects, consider using automated application systems, such as spray equipment or metering systems.

These tools enhance efficiency, reduce waste, and guarantee consistent application rates. Regardless of the method, it's crucial to follow the manufacturer's recommended mixing techniques and application guidelines to achieve ideal adhesion.

Curing and Protection Options

After applying the adhesive, frequently, the next vital step is to confirm proper curing and protection of the bond. You must guarantee the adhesive sets correctly to achieve ideal adhesion. Curing methods play a significant role in this process. There are various curing methods to choose from, depending on the specific requirements of your project.

| Curing Method | Description | Benefits |

|---|---|---|

| Moist Curing | Apply a layer of water or curing compound to the surface | Promotes hydration, reduces shrinkage |

| Dry Curing | Use a breathable membrane to retain moisture | Prevents water ingress, reduces efflorescence |

| Accelerated Curing | Apply heat or specialized chemicals | Reduces curing time, increases productivity |

In addition to curing methods, protective coatings can be applied to the concrete surface to enhance durability and resistance to environmental factors. These coatings can be epoxy-based, polyurethane-based, or acrylic-based, each with its own set of advantages and disadvantages. By selecting the appropriate curing method and protective coating, you can confirm a strong, long-lasting bond between the concrete and the adhesive.

Testing and Inspection Tools

Your concrete adhesive project's success hinges on ensuring the bond between the adhesive and the concrete substrate is strong and durable. To achieve this, you need to verify the adhesion quality through testing and inspection. This vital step helps identify any potential issues early on, saving you time and resources in the long run.

You'll want to utilize the following testing and inspection tools:

-

Pull-off testers: Measure the bond strength between the adhesive and concrete by applying a controlled force to a bonded area.

-

Tensile testers: Evaluate the adhesive's tensile strength by applying a gradual load to a test specimen.

-

Shear testers: Assess the adhesive's shear strength by applying a controlled force parallel to the bonded surface.

-

Acoustic emission testing: Detect defects or weaknesses in the bond by monitoring high-frequency acoustic signals generated during testing.

-

Visual inspection tools: Utilize magnifying glasses, microscopes, or other visual aids to examine the bond for signs of defects, such as cracks, voids, or delamination.

Frequently Asked Questions

Can a Single Adhesive Work for Multiple Concrete Types?

You'll find that a single adhesive rarely works seamlessly across multiple concrete types, as adhesive compatibility is heavily influenced by concrete diversity, making it vital to select an adhesive tailored to your specific concrete substrate.

Are There Any Eco-Friendly Concrete Adhesion Options Available?

You're looking for eco-friendly concrete adhesion options; fortunately, sustainable adhesives and natural binders are emerging as viable alternatives, offering reduced environmental impact without compromising performance, and they're worth exploring for your next project.

What Is the Ideal Temperature for Concrete Adhesion?

When you're applying concrete adhesion, you'll want to guarantee the ideal temperature ranges from 50°F to 90°F (10°C to 32°C), as extreme temperatures affect bonding, and consider humidity levels between 40% and 60% to prevent moisture interference.

Can Concrete Adhesion Tools Be Used With Other Materials?

When you venture beyond concrete, you'll find that surface preparation and adhesive application tools can be adapted for use with other materials, such as epoxy, polyurethane, and acrylic, but you'll need to adjust settings and techniques for ideal bonding.

How Often Should Concrete Adhesion Tools Be Replaced?

You should replace concrete adhesion tools regularly, as part of routine tool maintenance, to guarantee peak performance and prevent adhesive lifespan degradation, typically every 6-12 months or as manufacturer-recommended, to maintain bond strength and reliability.

Conclusion

You've got the right tools for concrete adhesion success. With the right adhesives, surface prep, mixing and application tools, curing and protection options, and testing and inspection tools, you're set for a strong bond. Did you know that a 1% increase in concrete surface roughness can increase bond strength by up to 20%? Optimize your process with the right tools and take advantage of this significant improvement.

Related Posts

-

Must-Have Handheld Tools for Concrete Repair

When tackling a concrete repair project, it is crucial to have the right handheld tools to achieve a professional fin...

-

Essential Power Tools for DIY Concrete Sculpting

As you begin DIY concrete sculpting, you'll need a strategic selection of power tools to achieve professional-grade r...

-

What Tools Are Needed for Concrete Wall Foundations

You'll need a thorough array of tools and equipment to construct a concrete wall foundation that meets structural int...